Q Acoustics Concept 500 Floor Standing Speakers in Silver + Ebony RMS 25-200w

Elevate your home audio experience with the Q Acoustics Concept 500 Floor Standing Speakers. Expertly crafted with a triple-layer cabinet construction and Gelcore, these speakers deliver a balanced, natural, and dynamic presentation. With a sensitivity of 90dB and a nominal impedance of 6?

, the Concept 500 speakers feature two 165mm (6.5) mid/bass drivers, Point-to-Point (P2PT) bracing, and Helmholtz Pressure Equalizers (HPET) to control panel resonance. These speakers are compatible with a wide range of quality amplifiers and receivers, and come in a sleek Gloss Silver + Ebony finish. The overall height is 1175 mm (46.2 inches), and the overall length is 375 mm (14.8 inches). The Q Acoustics Concept 500 speakers are a great addition to any home audio system.

Q Acoustics have until now concentrated on designing and marketing loudspeakers that most would agree focussed on the budget end of the market. The objective with the Concept 500 was to concentrate on a pertect balance between art and science to produce a loudspeaker that would be stylish, contemporary, fine-sounding and accurate with less priority on price. The Concept 500 has been developed by Q Acoustics in collaboration with Fink Audio-Consulting and DA with whom they have built a long-term partnership since working together on their very first loudspeaker project over 10 years ago.

In the new Concept 500, this truly talented team of people have produced a beautiful loudspeaker that can be manufactured so consistenty that the sound and performance of every unit will be identical from first to last. The Q Acoustics Concept 500 is a high-end floorstanding loudspeaker designed for audiophiles seeking both sonic excellence and contemporary style. It is the flagship model in the Q Acoustics Concept range, known for its advanced engineering and refined sound. Founded in 2006, Q Acoustics quickly built a reputation for designing and manufacturing class-leading loudspeakers. Concept 500 is the culmination of Q Acoustics continual evolution and refinement resulting in what we believe is sonic perfection.

Designed to appeal to discerning audiophiles, the Concept 500 achieves a perfect balance between art and science. It is a loudspeaker that is at once, stylish, contemporary, fine-sounding and astonishingly accurate. It couples low directivity with wide bandwidth, good sensitivity and sensible impedance. This makes the new Concept 500 both room-friendly and an easy load to drive, allowing amplifiers to deliver their best performance. To create a stereo soundstage which gives as good an impression of width, depth and height as that found in a live performance requires high quality drive units, a well designed crossover and an accurately constructed cabinet.

To achieve this, Q Acoustics formed a truly talented team with many years of experience in the design, engineering and manufacture of world-class loudspeakers. A combination that resulted in a state-of-the-art loudspeaker worthy of any high-end system. The Concept 500 is available in three stunning dual finishes to ensure that they fit perfectly into your listening environment. Gloss Black / Rosewood, Gloss White / Light Oak and Silver / Ebony finishes show Concept 500 in a minimalist form, a seamless addition in busy design environments with real Italian veneers at the rear giving an understated and effortlessly stylish nod to Concept 500's high end speaker credentials. The purpose of a good hi-fi system is quite simply to enhance the musical experience of playback at home. To get something that even resembles the real thing (and whatever anyone says this is the closest the hi-fi industry ever gets) a stereo image that gives as good an impression of width depth and height as would be found at a gig or a concert is needed. Good quality drive units, a well-designed crossover and a properly constructed cabinet can achieve this, but of these the cabinet itself is absolutely paramount. The unwanted noise created by sympathetic vibrations in a loudspeaker cabinet tends to be exaggerated only at certain frequencies and is not coherent in its phase relationship with the program material. Some frequencies will be reinforced, some will cancel and it is important to realise that all this happens at a very low level where the ambient clues about time and space exist to help create the stereo image.The random noise created by poorer, noisier enclosures dramatically reduces image stability and consequently the illusion of reality. Unfortunately most manufacturers overlook this very important area. They concentrate only on maximising dynamic range and how loud a speaker will play with respect to the effects of dynamic compression.

This neglects the equally important area of how softly it can play and how silent the cabinet can be made. High-end speaker manufacturers often espouse the exclusive use of natural wood cabinets as a superior construction material or even reject this in favour of significantly more expensive and exotic alternatives. Wooden cabinets, it is true, can bring some benefits; wood is well self-damped, is easy to cut to shape and is reasonably inexpensive. However, Q Acoustics have found that fibre boards such as MDF still have the advantage; they are even easier to cut, fit and finish but crucially, because they are not totally homogenous in their makeup, they are very well damped, avoiding high Q resonances.For these reasons Q Acoustics use these materials in preference to more esoteric alternatives which only really offer extra mass and expense for very little sonic benefit; the difference lies in how the cabinets are designed, measured and tested in order to maximise performance. Often, much is made by other manufacturers of having cabinets heavily supported by solid.

Shelf-type bracing to lend extra rigidity to the loudspeaker. Shelf-type bracing can be effective, but the disadvantage is that it can also transfer noise and vibration to all the other panels thus spreading the energy to a larger surface area. This design when used indiscriminately tends to be the reserve of manufacturers who only have access to rudimentary or outdated test and measurement techniques.

Fink Audio-Consulting has evolved proprietary computer models which accurately predict ideal cabinet construction and stiffening methods in an easily repeatable manner. Through the use of Finite Element Analysis and Laser Interferometry the exact performance of the cabinet structure can be minutely and accurately analysed to reveal the exact positions which need support and those areas which do not. The resulting bracing method, known as Q Acoustics P2PT (Point to Point) bracing, only supports the parts of the cabinet that need to be stiffened and does not spread unwanted energy randomly. Where velocity is greatest the area is coloured towards the red end of the spectrum and where it is least it is coloured towards the blue end. Conventional bracing would allow this movement to be transferred to adjacent panels but Q Acoustics P2PT allows the design team to apply bracing only in exactly the correct places. Whereas Q Acoustics P2PT bracing deals with low frequency panel vibrations, higher frequency cabinet noise is dealt with by the use of Dual GelcoreT which is a development of the same GelcoreT technology used to great success in the Q Acoustics Concept 20. The speaker cabinet is constructed in three separate layers rather like a room within a room and the resulting interstices are completely filled under pressure with a compliant form of non-setting gel.The two constrained layers effectively damp the walls of the speaker cabinet by converting higher frequency vibrations into heat, which is then dissipated harmlessly within the damping gel. Any erroneous boost or cut in level at this frequency can affect the perception of musical timbre and contribute to listener fatigue. Tall loudspeakers all tend to suffer from what is often known as organ pipe resonance.

A rather dramatic term used to describe areas of high and low pressure within the enclosure. Q Acoustics engineers designed a Helmholtz Pressure Equaliser (HPE) to be positioned inside the cabinet to assist in balancing pressure irregularities.

The HPET tubes convert pressure into velocity reducing the overall pressure gradients within the enclosure. There are two additional aspects of loudspeaker cabinet design which are so obvious that they are often overlooked completely and they both revolve around drive unit fixing. Firstly, unattractive screws or bolt heads need to be hidden and conventionally this requires solidly fixed decorative trims which at the same time need to be easily removable should servicing be required. Secondly and more importantly is a problem that besets most loudspeakers - that of drive unit mounting bolt torque stability. Over time most conventional screws or bolts can loosen due to vibration in the loudspeaker cabinet.

A performance improvement can usually be achieved by regularly tightening the drive unit screws (maybe every six months) to the designer prescribed torque. The problem is that most hi-fi owners don't have a torque adjustable screwdriver and the degradation in sound quality is so slow and gradual that one barely notices. The Concept 500 solves both the above problems in a simple and elegant way.

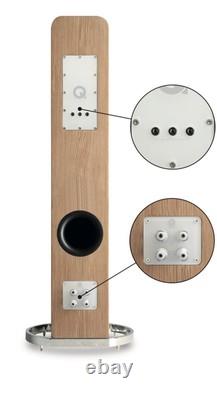

The drive units are held in place from behind by strong spring tensioned retaining bolts, keeping the torque constant and obviating the need for decorative trims. A speaker that doesn't sit solidly on the floor - one that rocks on its base - will not be able to deliver its ultimate performance because the speaker cone energy will not be transferred to the surrounding air in a completely linear way. The cast aluminium base supplied with the Concept 500 is securely mounted to the bottom of the cabinet. It can be fitted with four sharp spikes or ball-end feet to immovably couple the loudspeaker to a variety of domestic flooring surfaces. It allows excellent adjustability to enable complete rigidity on sloping or uneven floors. Because the plinth is designed without large flat areas and is simply chrome plated without additional adornments it does not encourage the deleterious effects of unwanted acoustic reflections - the music will rock, the loudspeaker will not. What do all these cabinet benefits amount to? Signal to Noise Ratio really has become the forgotten specification in loudspeaker design.The ratio of effective mid / bass cone size to cabinet surface area on a floorstanding loudspeaker is quite large, so cabinet vibrations. Although small, can still be easily audible. On poor cabinets as little as 30dB difference between music signal and cabinet noise can be measured.

The scientific engineering approach adopted by Q Acoustics to the problems outlined above has resulted in a 30dB reduction in the power of unwanted cabinet radiation and noise across the board. That's a real 30dB increase in signal to noise ratio, or to put it more simply, that's a lot more music and a lot less noise. The partnership with Fink Audio Consultancy has granted access to skills and techniques that alone would have taken years to develop. It has also brought unparalleled contact with the world's best loudspeaker manufacturers and suppliers of specialist components. Together this has led to the design and production of a proprietary range of drive units which are used to create loudspeakers that are far better than their price tag might indicate. From the outset, in keeping with a policy of proprietary development, the 165mm mid / bass drive units were designed exclusively for the Concept 500 project so that each aspect of the design was tailored to Q Acoustics precise requirements. The cone is precision formed from impregnated and coated paper and is teamed with a newly developed low-hysteresis rubber surround, which helps to reduce unwanted cone resonances. The voice coil has an uncommonly large diameter of 35mm. Instead of Kapton® or aluminium, the voice coil former is made of glass fibre which delivers the required stiffness but without the unwanted effects of eddy currents within the tormer. The voice coil uses an unusual 2+2 copper clad aluminium winding CCAW configuration. The two dual layers of CCAW conductors are wound in parallel, which gives the voice coil increased force for a given current input compared to a normal dual layer winding, without adding extra mass.Higher distortion can sometimes be caused by this arrangement but it is eliminated by adding an aluminium inductance compensation ring to the motor system and a copper cap to the top of the pole piece. Low distortion drive units and a very quiet cabinet can ruthlessly expose a poor crossover. This means that not only must the design of the crossover be exemplary but great care must be taken when choosing components. For instance, the laminated silicone steel core main inductor that had originally been specified introduced too much distortion and was obviously colouring the sound when compared to the amplifier output.

Instead, despite its physical size and associated mounting difficulties, a massive 10cm x 10cm Mundorf aircore inductor was chosen for the Concept 500. Securely mounted inside the base of the loudspeaker the inductor introduces virtually zero noise and distortion.For the same reason the crossover. Uses high grade polypropylene film capacitors including a Mundorf Supreme in series with the high frequency unit. The resistors are custom made bifilar wirewound types with astonishingly low inductance. The overall topology of the crossover is 4th order acoustic Linkwitz-Riley which gives an excellent response on and off-axis, further strengthening the room-friendly character of the Concept 500. The nominal impedance is a deliberately sensible 62 with an absolute minimum of 3.7 which makes the speakers relatively easy to drive.

The terminal panel and rear access panel are designed in such a way that they are prevented from vibrating in sympathy with the music. It is surprising how often this can be a source of extraneous noise in many commercially available designs.

The rear access panel in particular has been constructed by sandwiching layers of MDE, steel and bitumen to maintain the integrity of the Dual Gelcore'T cabinet. The Concept 500 is equipped for bi-wiring or bi-amping with electrically isolated and oversized HF and LF terminals which can accept bare wires, spades or 4 mm banana plugs. If connected using a single run of cable the best pertormance will usually be obtained using bi-wire links made from the same cable as the speaker cable.